E-mail: btomo@mail.ru; mail@btomo.ru.

+7 (351) 245-06-17, 247-74-42, 729-81-25

Scientific information

Geometric Parameters of Cycloidal Gear

The available technical literature provides insufficient information to the issues of cycloidal gear (CG) configuration. The literature sources give the examples of the simplest CG configurations, in particular, those consisting of gear wheels which differ only by one tooth and having only one circuit design with an output shaft connected to rundles [1,2]. Such gears have a gear reduction rate equal to the number of teeth at the smaller gear (external one) and the output shaft direction opposite to the input one.

More

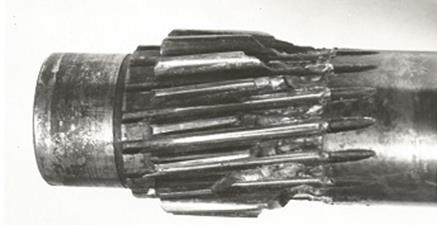

Shaft-to-Sleeve Connections with Unified Involute Spline

A wide application of shaft-to-sleeve connections in the form of gear structural components causes the need in finding the ways to increase their quality and efficiency of use. Spline connections are the most widely applied in gears, both straight-sided ones with a zero profile angle and the involute ones with a profile angle of 30. As a production item it is a knowledge- and labour-intensive gear component with increased requirements to the manufacture and reliability quality. The key type of such connections' failure - spline collapse as it is shown, for example, in (Fig. 1).

More

Selecting Rational Method to Restore Part Worn-Out Surfaces

The article provides the sequence for work performance on selecting a rational method to restore worn-out part surfaces. It contains analytical dependencies to define the factors for wear resistance, fatigue and adhesion resistance as well as a generalized durability factor. The paper demonstrates aggregative values of these factors for various restorative maintenance methods. The author also gives the dependences to define technical and economic criteria of the proposed restorative maintenance methods.

More

Worm Hobs with Multipair Engagement

The innovative way to secure reliability and quality of worm hob is to decrease the load in the contact zone while passing to multipair contact and to increase the fabricability due to the unification of initial and generating worm.

More

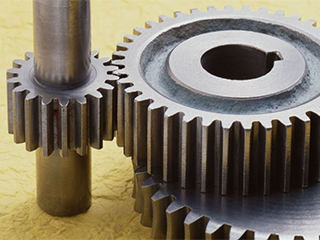

Synthesis of Bevel Gears with Multipair Engagement

Bevel gears with straight or circular teeth are widely used in transmission assemblies of various intended uses. However, cases of gear failure due to teeth wear, pitting or cleavage are rather common (Fig. 1).

More