Special equipment

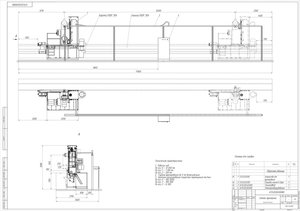

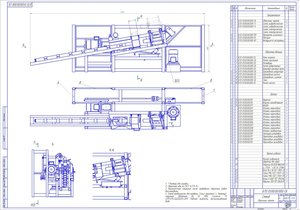

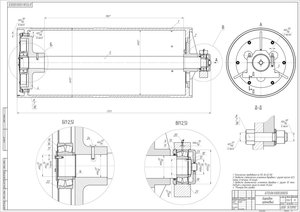

Edge planer 7814

Produced by “MZOR” Belorussia and modernized into edge milling machine: the planer head was replaced with cutter one, infinitely variable speed control of the mill 60…1000 rpm. Outdated elements of hydraulic and electric equipment were replaced with modern ones. Universal milling with any angle of the edge milled is possible. The machine performance is increased by more than 2.5 times.

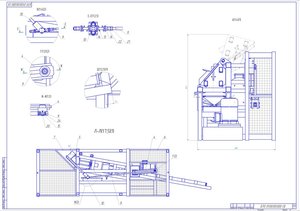

Design and construction of technological bench for reinforced steel tests

Protected with thermal converter (muffs). The working length of muffs is up to 2 meters, the test pressure is up to 1000 at. (!). The bench allows testing flanged and thread muffs thus replacing two different benches.

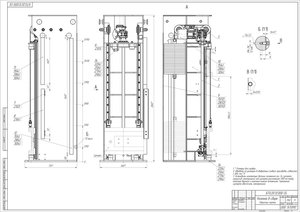

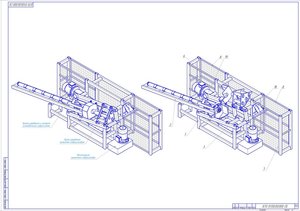

Pleated mesh machine

The equipment is designed for MIC solutions. The electric mechanical machine is intended to produce pleated filtering mesh of different configuration with 0.3 to 1.2 mm thickness by rolling an out-of-tolerance workpiece between tooth rolls. An industrial programmed drive as a bench component as well as the bench construction itself allow both manual and automatic management.

Maximum performance is up to 10m/min.

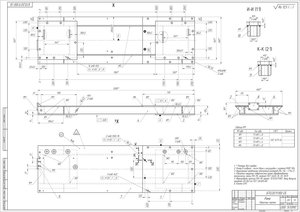

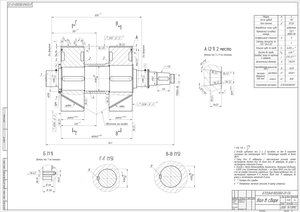

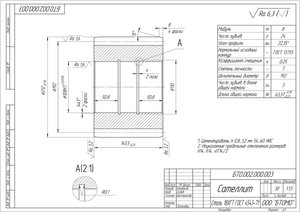

Design and construction of pouring crane load drum

Its load capacity is 50 tons. The drum pressurizer was designed in accordance with the customer’s sample. The drum diameter is 975 mm, the drum length is 2,460 mm, the drum wall thickness is 31 mm (without grooving). The drum drive is accomplished with a gear reducer C2-1000.

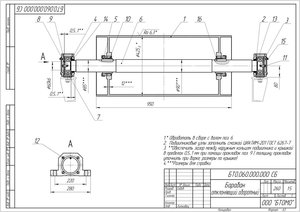

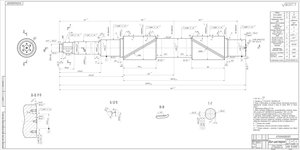

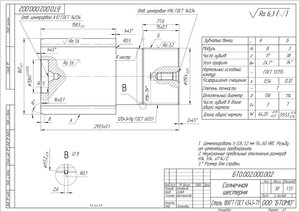

Design and construction of conveyor idler pulley

The diameter is 425 mm, the length is 950 mm, the wall thickness is 14 mm. The drum pressurizer has been designed in accordance to the existing drum sample provided by the customer. Besides, as a result of the initial sample damage (break of drum bearing journal), strength calculation has been conducted showing the necessity to increase the diameter of the drum bearing journal.

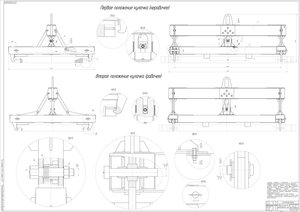

Crosshead design and construction

To lift and transport the air field slab Pag-18, form Pag-18. The crosshead allows automatic grip of slabs and forms without any manual work. The general weight of slabs and forms is 12.100 kg.

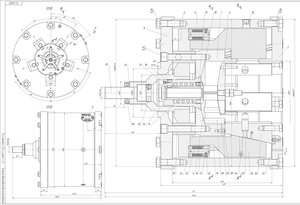

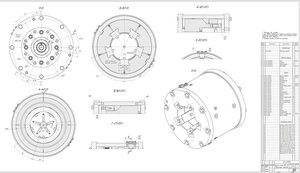

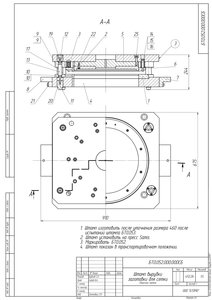

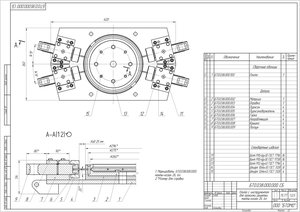

Design and construction of self-aligned wedge-like, self-tightening chuck for MAM-215 unit

For setting and rolling the joint boxes on oil assortment pipes. The maximum diameter of the joint box tightened is 215 mm.

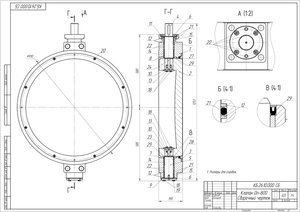

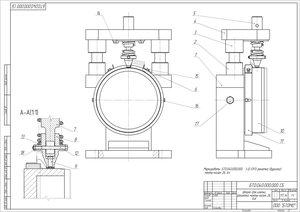

Design and construction of replaceable analogue for throttle flap, make G type O (DN800) by linde ag in oxygen plant of metallurgical unit

The cost is 1.7 times lower as compared with the imported one. No complaints in terms of its operation.

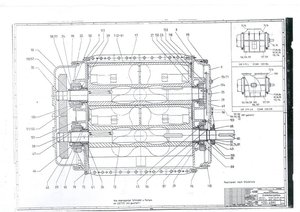

Repair of vacuum compressor GM 430S/580L (Aerzener Maschinenfabrik G.M.B.H) in oxygen plant of metallurgical unit

Design and construction of new side base lids, rotor repair and balancing. The result: the unit has been working satisfactorily with no problems for three years up to 08.07.2016.

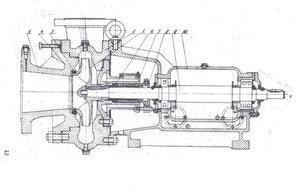

Upgrade and repair of electric driven pumps NKU-90 M-C

As a result of the upgrade, the time of technological assembling/disassembling is reduced and repair-to-repair time is increased two times (!).

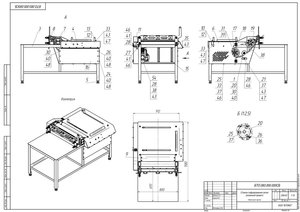

Die tooling

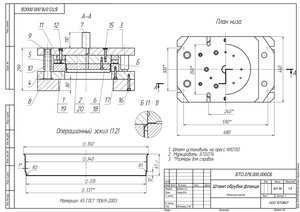

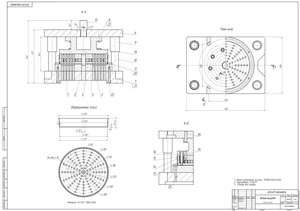

Project “Manty-Kazan 6 l” and “Manty-Kazan 15 l”

Design and construction of dies for a complete technological cycle of product construction. Peculiarities of the project: tooling for “manty-kazan 6 l” has been designed for the German press machine PAUST-320 allowing simultaneous usage of 4 dies in line. The Russian and Italian press equipment is used for “manty-kazan 15 l”: the press Omera-120 (Italy), the press PG-30 (Russia), the press KI 2130 (Russia), the press AA 62-28 (Russia). The given project includes the following kinds of dies: blanking, cupping, cropping, reducing, piercing, staving.

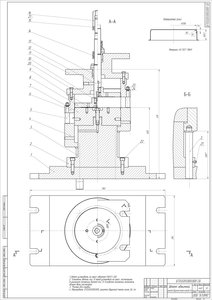

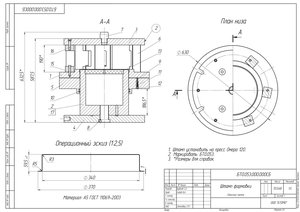

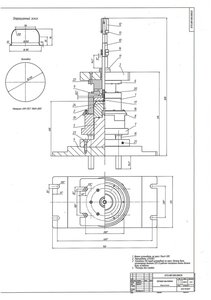

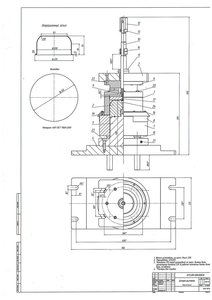

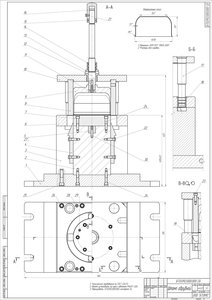

Design and construction of die tooling (cupping and reducing dies)

For manufacturing the products “Saucepan” of 1.7 and 3 liters. Dies are set in the press machine PAUST (Germany) with pressure of 320 tons. Die pressurizer has been designed in accordance with the product drawings provided by the customer. Die parameters: shut height 614 mm, width 760 mm, weight 400 kg.

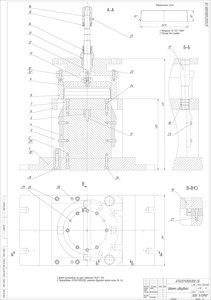

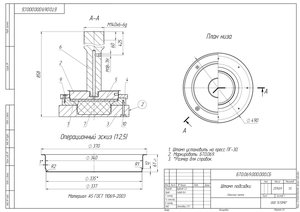

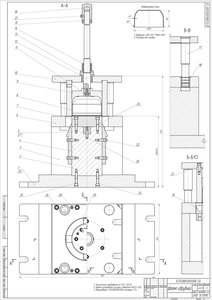

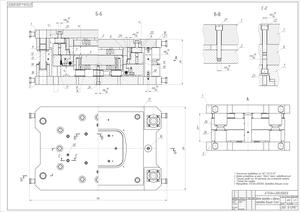

Import replacement: design and construction of combination die (blanking and cupping)

For manufacturing the complete product “Drip pan” in food industry. The design documents for die tooling has been accomplished in accordance to a worn-out sample produced in Italy. The die is set to the press Omera (Italy) with the pressure of 120 tons. Die parameters: shut height 318 mm, width 965 mm, weight 890 kg. The product is being exploited at the moment.

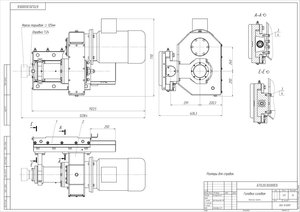

Reducers and gear wheels

Design of pressurizer and construction of tooth couple of Skoda multiplicator for turbocompressor DANA drive in gas compression facility

High speed and heavily loaded cylinder herringbone gear (with rotation frequency 6,000 rpm, transmission power 2.4 MW. The drive gear shaft weight is 1,510 kg; the driven one’s weight is 217 kg. Tooth wheels are constructed from forged pieces V KP 70 (steel 34ХНЗМА) with the 4th degree of strength (GOST 1643–81), with the application of gear grinding and consequent dynamic balancing. Teeth were relieved to meet the strict demands for performance characteristics including low vibration and noise. The quality control management of the product on each stage of production guaranteed the product high quality.

Repair of planetary gear GB.21002FS of screw extruder drive SP 560/450 produced by rieter-werke GmbH (Germany), power 132 kWt

In the process of damage identification some broken details of an outbound planetary gear were detected and discarded. After the analysis and diagnostics in compliance with all the technical demands the duplicate details were manufactured: epicycle (crown tooth wheel), sun gear, satellites as well as shafts and liners. All the details were set into the original mounting seats inside the body frame, then we fulfilled the gear reducer assembly, running and acceptance tests.

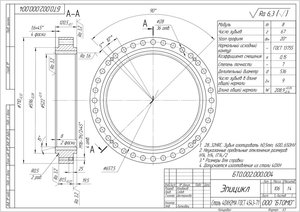

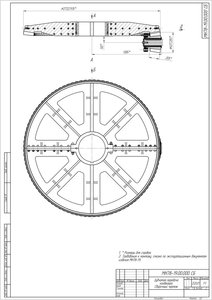

Design and construction of open tooth gear for multihearth roaster drive (manufacture of refractory products)

Heavily loaded bevel gear and pinion with the straight teeth, the parameters of the drive gear: m=26; z=12. The parameters of the driven wheel: m=26; z=96. The diameter of the driven wheel is 2.7 m, the weight is 1,439 kg. The material used is high-strength cast iron HDCI70 (VCh170) GOST 7293–85.