E-mail: btomo@mail.ru; mail@btomo.ru.

Shaft-to-Sleeve Connections with Unified Involute Spline

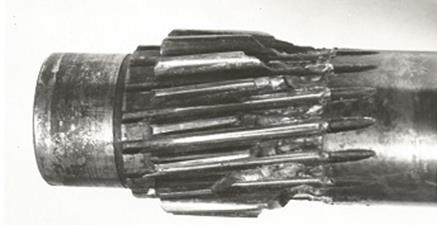

Fig. 1 Shaft with collapsed teeth

The increase in a bearing capacity, resource and producibility of spline connections is a complex scientific and technical problem. The known solutions - bearing capacity increasing by means of the dimensions' and manufacturing quality increase - are quite expensive if one applies a traditional technology. Other direction is a unification of spline geometry by their profile type and producing instrument. In case of the involute splines, a transition to the connections with involute teeth (like toothed couplings) can become a solution to the problem. This will allow for the use of a standard gear-cutting tool for their production, for example, worm hobs and gear cutters, and exclude the necessity to use expensive broaching tools. In gear wheels such connection can have a unified geometry in a model with a wheel rim as well which provides for a higher efficiency. In case of spline connection replacement by a gear one, teeth alignment will be performed along the lateral sides while their geometry - correspond to the geometry of internal teeth and be determined in compliance with the standard [2].

For the sake of comparison the Table 1 provides the results of the geometry and strength calculation of spline involute and toothed connections with a nominal diameter D=45, module m0= 3,number of splines z=13 and spline length l=35. A calculated gear cutter for a toothed coupling: 2537–0162 GOST 9323–79; module m0= 3, teeth number z0=9; teeth top diameter dα0=34.44; offset factor x0= -0,01. Number of shaft rotations N1= 450 1/min shaft rotational torque T1=6.5 kgf•m; shaft and coupling material steel 20X spindle hardness HRC = 60. All linear dimensions in mm while angular ones - in degrees. The index 1 relates to the shaft while the index 2 relates to the hub.

Table 1. The results of the calculation of spline and toothed connections

|

Name of parameters |

Spline connection |

Toothed connection |

|

Connection nominal diameter (calculated), DR |

45,0 |

45,0 |

|

Profile angle, α |

30 |

20 |

|

Reference diameter, d |

39,0 |

39,0 |

|

Basic circle diameter, db1/db2 |

33,78/33,78 |

36,65/36,65 |

|

Offset factor, x1/x2 |

0,45/0,45 |

0.43/0.43 |

|

Teeth top diameter, da1/da2 |

44,40/39,0 |

46.82/36,72 |

|

Teeth gullet diameter, df1/df2 |

36,72/46,32 |

34,08/48,32 |

|

Teeth depth, h1/h2 |

3,84/3,66 |

6.37/5,78 |

|

Teeth addendum, ha1/ha2 |

1,35/1,35 |

3,91/1,12 |

|

Teeth dedendum, hf1/hf2 |

2,49/2,31 |

2,46/4,66 |

|

Teeth reference thickness, sn1/sn2 |

6,27/6,27 |

5,65/3,77 |

|

Radial clearance, cr |

0,3 |

0,75 |

|

Base tangent length, W1/W2 |

23,57/23,57 |

23,57/23,57 |

|

Teeth number in the base tangent length, n1/n2 |

3/3 |

3/3 |

|

Dimensions along the rolls, M1/M2 |

47,65/34,60 |

47,0/34.62 |

|

Roll diameter, dr1/dr2 |

4,98/4,98 |

4,98/4,98 |

|

Teeth thickness on the top surface, sna1/sna2 |

3,0/6,27 |

1,71/3,01 |

|

Teeth addendum factor, ha1*/ha2* |

0,45/0,45 |

1,30/0,37 |

|

Teeth dedendum factor, hf1*/hf2* |

0,83/0,77 |

0,82/1,55 |

|

Safety factor at the contact |

1,5 |

1,5 |

|

Calculated contact stress, SIGMH1, kgf/mm² |

4,7 |

6,4 |

|

Allowed contact stress, SIGMHP1, kgf/mm² |

82,8 |

82,8 |

The analysis of the calculation results demonstrates that many geometrical parameters characteristic of the spline and toothed connections at the same initial data virtually coincide or have just slight differences. In general, it relates to the diameter dimensions and teeth and spline depths. In particular, the toothed connection compared with a spline one has an increased gullet diameter and a decreased diameter of coupling tops and, on the contrary, an increased shaft top diameter and a decreased gullet diameter. As it is seen from the Table, the teeth depth became higher as a result. At the same time, due to a larger curve of the involute surface, the contact stresses in a spline connection will be less comparing with a toothed one, and this is confirmed by the Table data. Taking into account that the calculated stresses shall always be smaller than the allowed ones, such spline replacement by teeth and, within the admissible limits, hardness decrease and connection dimensions increase shall be considered effective as the key effect is reached due to a higher fabricability and the opportunity to apply available gear cutting tools. At the full unification of the connection and gear teeth when their rack profiles and modules are the same, the tool variety can be reduced to the minimum, i. e., shaft, coupling and wheel rim teeth can be cut by one or two gear cutters with various teeth number.

The Table 2 provides the results for the gear wheel with the shaft having a nominal diameter 50, module 3, teeth number 15 and length 45 at the same basic rack profile and teeth module. The rack profile GOST 13755–81. A calculated gear cutter for a toothed coupling and wheel teeth: 2537–0174 GOST 9323-79; module 3; teeth number 12; teeth top diameter 43.62; offset factor 0.02. Shaft rotation number — 350 1/min; shaft rotation torque — 7.5 kgf ∙ m; shaft and coupling material steel 20Х; teeth hardness HRC = 60. Gear wheel: teeth number 25; module 3; teeth thickness 40; material — steel 20Х; hardness — 60. Indices 1 and 2 relate to the connection, the index 3 – to a gear wheel.

Table 2. Results of the toothed connection and wheel calculations

|

Name of parameters |

Shaft-hub connection

|

Toothed wheel |

|

Reference diameter, d1/d2,d3 |

45,0/45,0 |

75,0 |

|

Main diameter, db1/db2, db3 |

42,29/42,29 |

70,50 |

|

Displacement factor, x1/x2, x3 |

0,025/0,40 |

0 |

|

Teeth top diameter, da1/da2, da3 |

50,45/42,71 |

81,0 |

|

Teeth gullet diameter, df1/df2,df3 |

37,65/54,20 |

67,5 |

|

Teeth depth, ℎ1/ℎ2, ℎ3, |

6,40/5,75 |

6,75 |

|

Normal teeth thickness, sn1/sn2, sn3 |

4,77/3,84 |

4,71 |

|

Teeth thickness on the top surface, sna1/sna2, sna3 |

2,37/3,05 |

2,16 |

|

Roll diameter, dr1/dr2, dr3 |

4,98/4,98 |

4,98 |

|

Dimensions along the rolls, M1/M2, M3 |

51,30/40,51 |

81,34 |

|

Safety factor at the contact |

1,5 |

1,5 |

|

Calculated contact stress, SIGMH1, kgf/mm² |

78,8 |

54,8 |

|

Allowed contact stress, SIGMHP1, kgf/mm² |

82,8 |

82,8 |

As it is seen from the Tables, the design of connection with a toothed profile as well as with the same module both in a connection and a gear is viable in terms of the technology. Connection contact stresses will be higher than those in the gear due to a smaller load acting point radius. As a result, the gear working capacity at the set load will always be defined by the connection bearing capacity. To manufacture toothed connections and gear wheels with the same module, one can use a single tool in the form of a gear cutter which provides for the enhanced production efficiency.

Conclusions

1. The unification of the involute curve of spline connections and toothed engagement on the basis of the uniform basic and generating (at the same module) profile provides for: enhanced fabricability and reduced the labour intensity of the manufacture of “shaft-gear wheel” parts; minimizing the gear cutting tool variety and the need in expensive drawing tools; enlarging the opportunities to apply involute splines instead of other connection types, for example, key connections or straight-sided spline ones.

2.Such unification is the most efficient at the single-unit and small-batch production.

V. Z. Melnikov, Cand. Tech. Sci., associate professor of MSIU

References

1. GOST 6033–80. Involute Spline Connections with a Profile Angle 30. M.: Publisher of Standards, 1982. 74 p.

2.GOST 19274–73. Cylindrical Involute Internal Gears. Geometry Calculation. M.: Publisher of Standards, 1974. 26 p.