E-mail: btomo@mail.ru; mail@btomo.ru.

BTOMO, LLC, performs the build-up operation with the help of special alloys and restorative maintenance of general industrial parts: all the existing dimensions of crane wheels and wheel pairs of plant diesel units, flattening machine and rolling mills rolls, axes, conveyor rolls and continuous casting machine rolls, rods and pistons with the length up to 5 meters and, in certain cases, - with the lengths more than 5 meters. We also repair any rotating bodies, internal and external surfaces and holes.

Besides, we perform the restorative maintenance of the freeform and flat parts: hydraulic control boxes of pressing machines and pump body frames, die tooling, forging hammers, pads and sledge-hammers, mixer augers, etc.

ECONOMIC EFFICIENCY |

PART QUALITY AFTER REPAIR |

FUNCTIONAL COATINGS |

|

Build-up has a high economic efficiency (on average, not more than 25 – 30% of a new part cost), this method is also applied to restore complex and expensive parts. On average, 8-15 repair cycles are conducted before the replacement with a new assembly. The operation life of the parts after restorative maintenance is compared with the duration of the new spare parts’ operation. |

A built-up metal is quite similar to the main metal in terms of its composition and mechanical properties. If the requirements to the product are high, after the build-up operation and machining one conducts ultrasonic inspection and liquid penetrant tests but this stipulates for a different “coating” technology and the specialist qualification and, naturally, for a different cost. |

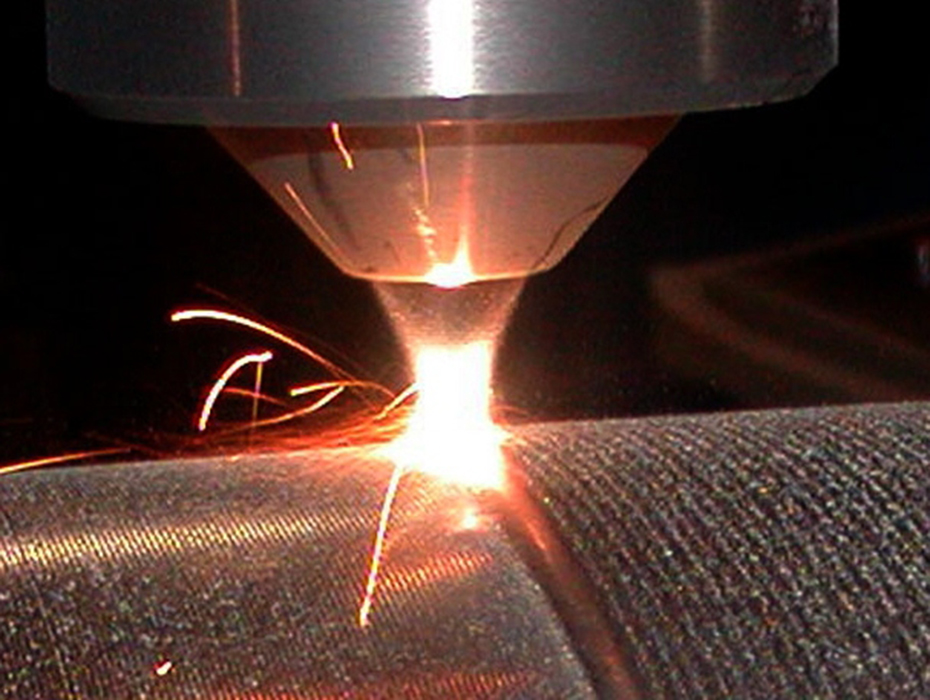

The build-up method provides for additional metal and alloy layer coating to obtain the surface layer with necessary functional properties. For example, the main metal provides for a necessary structural strength while the built-up metal brings special pre-set properties: wear resistance, necessary heat or corrosion resistance, etc. |

![]()

OUR STAFF PERFORM THE BUILD-UP AND RESTORATIVE MAINTENANCE OF PARTS AND ASSEMBLIES WITH VARIOUS FORMS, DIMENSIONS AND INTENDED USES.

|

Restorative maintenance of rotating bodies and parts with a circular section: |

|

|

|

Freeform and flat part repair |

|

|

|

Galvanic restorative maintenance |

|

|

Напишите. Мы будем рады Вам помочь!