E-mail: btomo@mail.ru; mail@btomo.ru.

+7 (351) 245-06-17, 247-74-42, 729-81-25

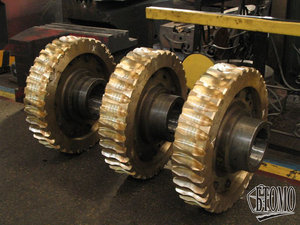

Gear wheels

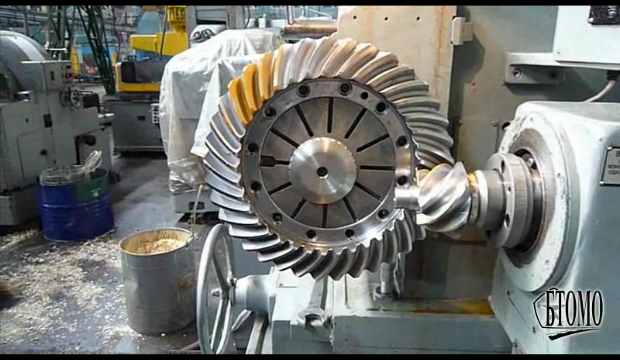

Gear wheels with conical straight, circular and hypoid teeth

-

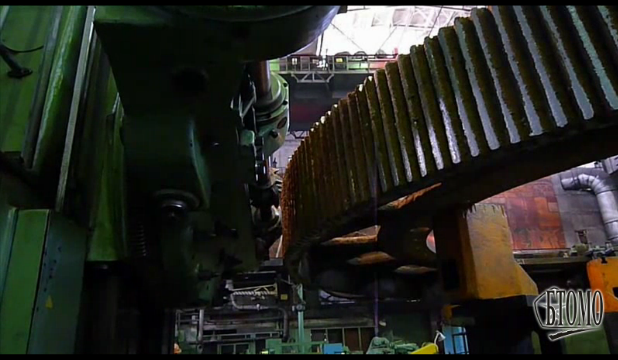

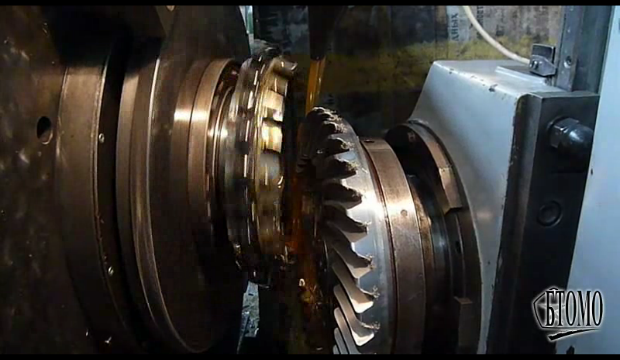

Зубчатая обработка венца крупномодульного_83

Зубчатая обработка венца крупномодульного_83

-

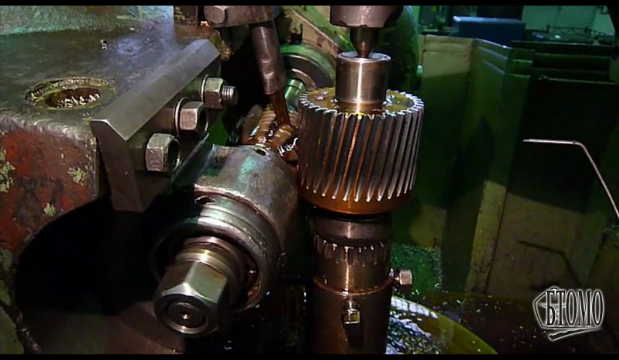

Нарезание зубьев шестерни цилиндрической косозубой_83

Нарезание зубьев шестерни цилиндрической косозубой_83

-

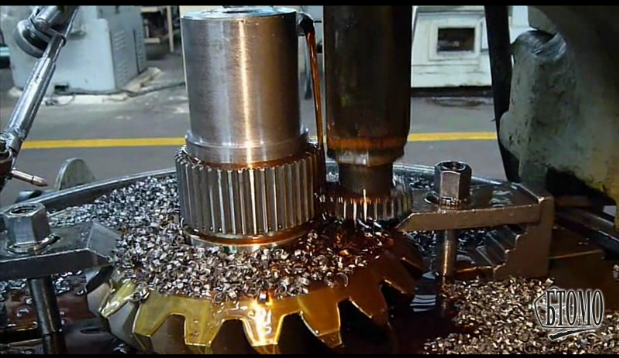

Долбёжная операция_83

Долбёжная операция_83

-

Нарезание зубьев шестерни конической с круговым зубом_83

Нарезание зубьев шестерни конической с круговым зубом_83

-

Начало нарезания зубьев венца зубчатого_83

Начало нарезания зубьев венца зубчатого_83

-

Окончание нарезания зубьев венца зубчатого_83

Окончание нарезания зубьев венца зубчатого_83

-

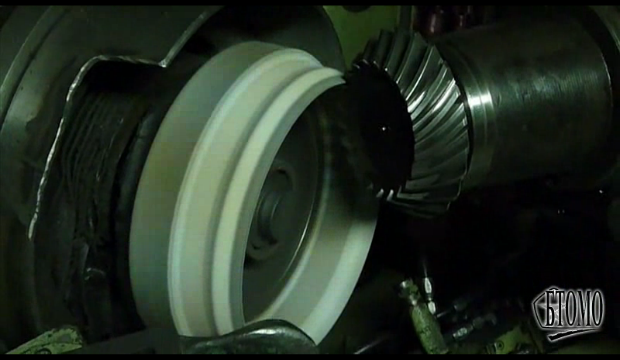

Шлифование зубьев шестерни конической с круговым зубом_83

Шлифование зубьев шестерни конической с круговым зубом_83

-

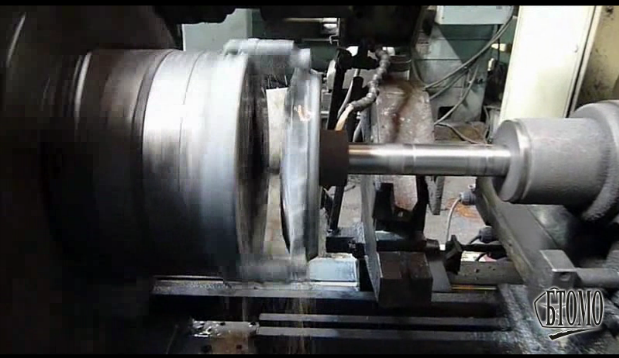

Шлифование посадочного отверстия венца зубчатого_83

Шлифование посадочного отверстия венца зубчатого_83

-

Контрольно-обкатная операция_83

Контрольно-обкатная операция_83